| QTY: | Price |

Supply Ability : 1000PCS/ Year

Quantity:

-

+

Total Cost :

Packing Information

Pcs/Carton: N/A

Packing Size/Carton:N/A

Packing Vol/Carton: N/A

N.W./Carton: N/A

G.W./Carton: N/A

QTY in 40HQ: N/A

QTY in 40GP: N/A

QTY in 20GP: N/A

1. Application

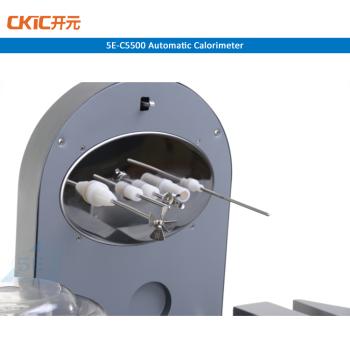

5E-C5500 Automatic Calorimeter is used to determine the calorific value of solid and liquid combustiles including oil, coal, coke, foodstuffs, SRF and biomass products. The calorific value is a crucial characteristic for each substance, also the key point to calculate the price of coal, so it will directly affect the economic benefits of the customers. This technique is widely applied in power plants, coal mines, metallurgy, chemical industry, commercial inspection, scientific research, etc.

2. Features

a. True Isoperibol Calorimeter

The jacket surrounding the vessel is kept at constant temperature with an accuracy to 0.1℃ during analysis.Mechanical supports for the vessel are made of a very lowthermal conductivity plastic. To minimize convention,water is added on the sides,top and bottom of the bucket.

b. High Automation and Efficiency

(1) 10 minutes analysis time by dynamic method, without compromising accuracy or precision.

(2) Optional second bomb operation minimizes down-time because the second bomb and sample can be prepared while the current sample is being analyzed.

(3) Two calorimeters can be controlled by one computer.Sample mass can be transferred to PC directly.

c. Optimized Design for Reliable Test Result

1.A reliable quantitative measuring cup ensures stable water volume of the bucket.

2. Closed-loop water circulation assures the purity of water system without any additional solution.

3. Filter in the bucket purify the water in circulation system.

4. Visible water level indicates the water volume, making it easy to feed sufficient water anytime to minimize the influence of water loss.

3. Specification

| Model | C5500 Automatic Calorimeter | |

| Conforms to Method | ASTM D5865, ASTM D4809, ISO 1928, ISO 9831 and GB/T213 , GB /T30727 | |

| Precision(1g Benzoic Acid) | 0.05%RSD* | |

| Measuring range | Up to 40MJ/kg | |

| Temp.Resolution | 0.0001°C | |

| Control Ability | 2 Units/ 1 PC available | |

| Analysis Time per Sample | Quick Method: 10min, Classical Method: 15mins | |

| Test Per Hour | Single control | Double control |

| Up to 6 | Up to 12 | |

| Jacket Type | Isoperibol | |

| Bomb Identification | Automatic (Up to 2) | |

| Balance Connection | Available | |

| Network Connection | Available | |

| Oxygen Fill | Semi-Automatic | |

| Bucket Fill | Automatic | |

| Structure | Benchtop or Vertical | |

| Bomb Vessel Lifting | Manual | |

| Power Supply | AC220V±10%, 50Hz/60Hz,<=500W | |

| Net Weight | Benchtop:75kg; Vertical:103kg | |

| Dimensions(L×W×H) |

Benchtop :Analysis unit: 480mm×500mm×420mm; Temp. control unit: 370mm×500mm×420mm |

|

| Vertical: 480mm×500mm×940mm | ||

| *Test Condition: 1.Ambient temp 20 °C ±1 °C,humidity75% ±5% 2.No strong interference source nearby 3.Clean water circuit with distilled water |

||

Test Data

| Calibrate mass,g | Temperature rise | ℃ or °F | As-determined heat capacity | units |

| 0.8107 | 2.1783 | ℃ | 9885 | J/K |

| 0.8115 | 2.1811 | ℃ | 9887 | J/K |

| 0.8881 | 2.3862 | ℃ | 9888 | J/K |

| 0.9111 | 2.4498 | ℃ | 9880 | J/K |

| 0.9746 | 2.6188 | ℃ | 9885 | J/K |

| 0.9935 | 2.6735 | ℃ | 9878 | J/K |

| 1.0927 | 2.9393 | ℃ | 9879 | J/K |

| 1.2052 | 3.2391 | ℃ | 9880 | J/K |

| 1.1251 | 3.0238 | ℃ | 9889 | J/K |

| 1.2214 | 3.2827 | ℃ | 9879 | J/K |

| Average:9883 J/K | RSD:0.043% | |||

|

Remark:ASTM-D5865,the precision of ten acceptable calibration test run shall have a relative standard deviation (RSD) no greater than 0.17%and CKIC's specification is less than 0.05%RSD.

Conclusion:5E-C5500 Automatic Calorimeter exceeds the ASTM Precision Requirement. |

||||

4. Our Company

5. Case Study

6. Service

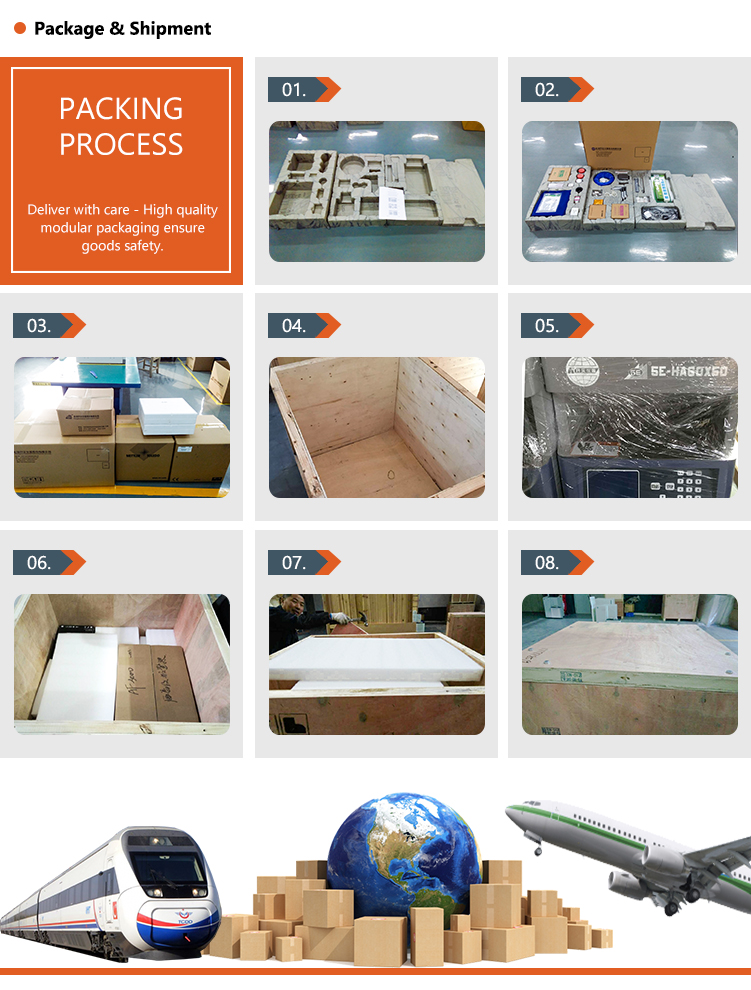

7. Packaging