| QTY: | Price |

Quantity:

-

+

Total Cost :

Packing Information

Pcs/Carton: N/A

Packing Size/Carton:N/A

Packing Vol/Carton: N/A

N.W./Carton: N/A

G.W./Carton: N/A

QTY in 40HQ: N/A

QTY in 40GP: N/A

QTY in 20GP: N/A

Compact drayers combine the fuction of dehumidifying, drying and twopstage conveying

BCD Series

"All-in-One" compact dryers

General Description

The BCD series “ALL-in-one” compact dryers combine the function of dehumidifying, drying and two-stage conveying into one single unit, specified for the production of ″Optical grade″products, such as lenses, LCD backlight panel, compact dissects. They have many applications in processing plastic materials, such as PA, Pc, PBT, PET etc. They feature honeycomb rotor for dehumidifying, ensuring continuous and constant low dew point. Under ideal conditions, it can provide lower than -40℃ dew point dehumidified air.

BCD-160U/120H

Features

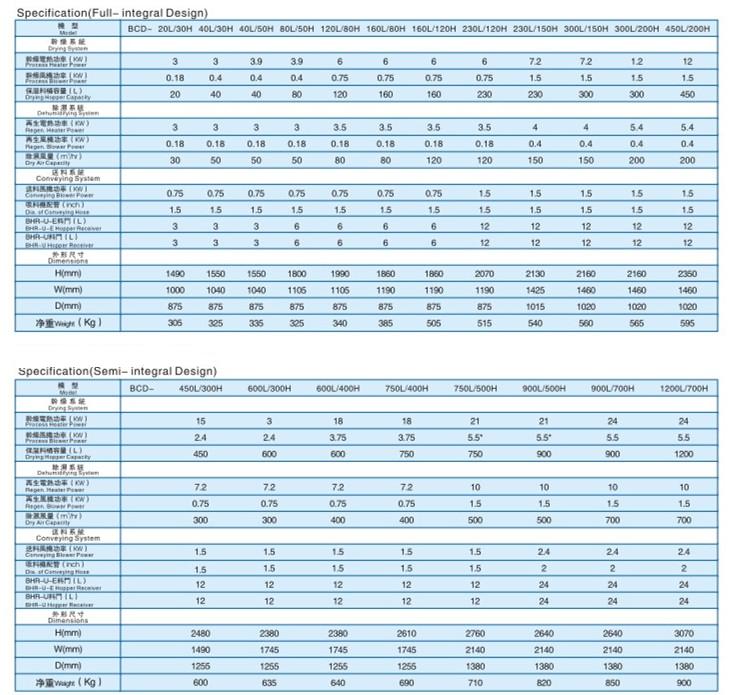

Specification

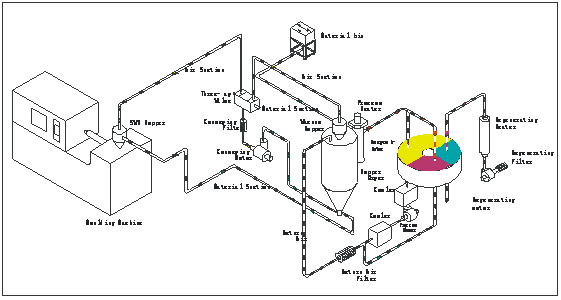

Working Principle

Drying and demoisture section: the hot and moisture air backing from the dry hopper drum will be blown into the honey comb type rotation wheel. The moisture contained in the air is absorbed by the rotation wheel. The moisture contained in the air is absorbed by the rotation wheel, and after that, the moisture will be de absorbed by the regenerated heating air. The two air streams work together in the rotation wheel. With the rotation of the wheel, the moisture in the air will be absorbed and de absorbed by the re generated air to drain out continuously, and to form a steady low dew point air. And this air will be heated to the dry temperature of plastics, and to be blow into dry hopper drum to form a closed loop. That is drying principle.

Feeding section: material absorption means absorption materials from the storage drum and other buckets into the dry hopper drum. When the magnetic proximity switch of vacuum hopper detects no materials in the hopper drum, the absorbing motor will start to visualize the hopper, and the materials in the storage buckets will be absorbed into the vacuum hopper drum under the pressure differential. When finish the absorption, motor will stop, and the materials will drop down in the dry drum under itself gravity. The principle of materials feeding and absorbing are the same, except that, under feeding materials, the materials from the dry drum are sent to the magic eye hopper and other type hopper installed in the plastics former.