| QTY: | Price |

Supply Ability : 500SET/ Month

Quantity:

-

+

Total Cost :

Packing Information

Pcs/Carton: N/A

Packing Size/Carton:N/A

Packing Vol/Carton: N/A

N.W./Carton: N/A

G.W./Carton: N/A

QTY in 40HQ: N/A

QTY in 40GP: N/A

QTY in 20GP: N/A

Compressed Air Dryers integrates plastic drying and conveying for inection moulding machine and stand injection moulding machine when limited by height of the workshop

BCAD series

Compressed Air Dryers

General Discription

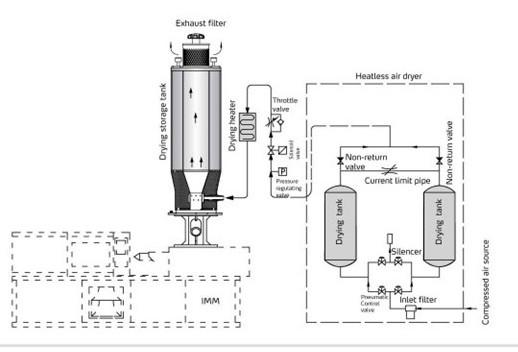

The BCAD series integrates plastic drying and conveying into one unit, which is specially applicable to injection moulding machine and stand injection moulding machine when limited by height of the workshop. The BCAD series adopts positive compressed air to load material, so it has low noise level and low energy consumption. Euro design features classy appearance and easy to maintain. The hot and dry air is formed by sending outfitted compressed air into electrical heater. Unique up blowing airpipe design makes hot air evenly spreadout to achieve the sufficient drying effect.

BCAD-12U

BCAD-12U

Outline dimensions of BCAD-12~40U

Outline dimensions of BCAD-12~40U

Features

Standard configuration

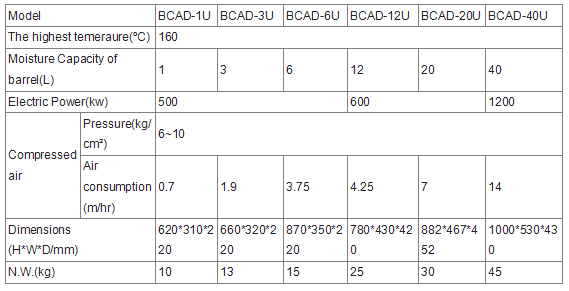

Specifications

Note:

1) The oil content of compressed air: ≤ 3mg / m³.

2) The machine voltage specifications: 1Φ , 230VAC,50Hz

Application

Application for small batch drying of commonly-used engineering plastics such as ABS and PS,also suitable for pre-heating treatment before plastics molding.

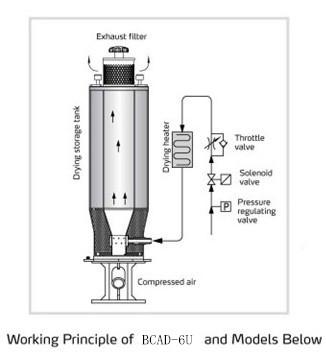

Working Principle

The working principle is that compressed air flows into heating case after through pressure regulating valve and solenoid valve and finally exhaust into air. At the same time, the dew-point is reduced.The heated compressed air is blown into the heat-preservation hopper to dry materials, and the exhaust into air through filter to remove water in raw materials.