| QTY: | Price |

Supply Ability : 5000SET/ Month

Quantity:

-

+

Total Cost :

Packing Information

Pcs/Carton: 1

Packing Size/Carton:N/A

Packing Vol/Carton: N/A

N.W./Carton: 40.0 kg

G.W./Carton: N/A

QTY in 40HQ: N/A

QTY in 40GP: N/A

QTY in 20GP: N/A

Euro insulated type hopper dryer with hot air down blowing design and using with honeycomb dehumidifiers to dry enineering plastics

BHD-U Series

Euro Insulated Type Hopper Dryers

General Description

BHD U series hopper dryers adopt hot air down blowing design and use stainless steel made material hoppers to avoid contamination. With this design, they are also ideally suitable for use with honeycomb dehumidifiers to dry engineering plastics. There are 25 models available, ranging from 20 to 8000 liters.

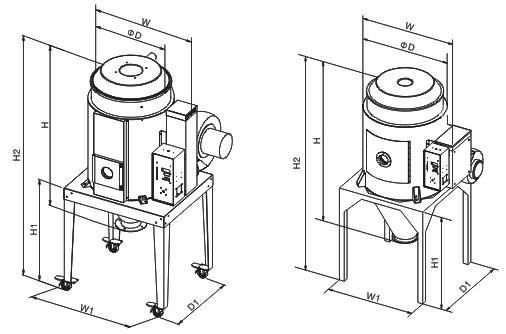

BHD-160U + Floor Stand and Suction Box

BHD-160U + Floor Stand and Suction Box

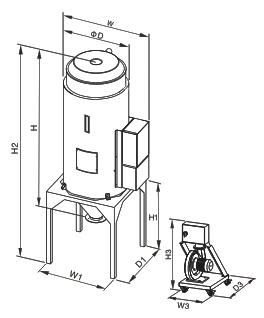

BHD-1500U and above + Floor Stand and Suction Box

BHD-1500U and above + Floor Stand and Suction Box

Features

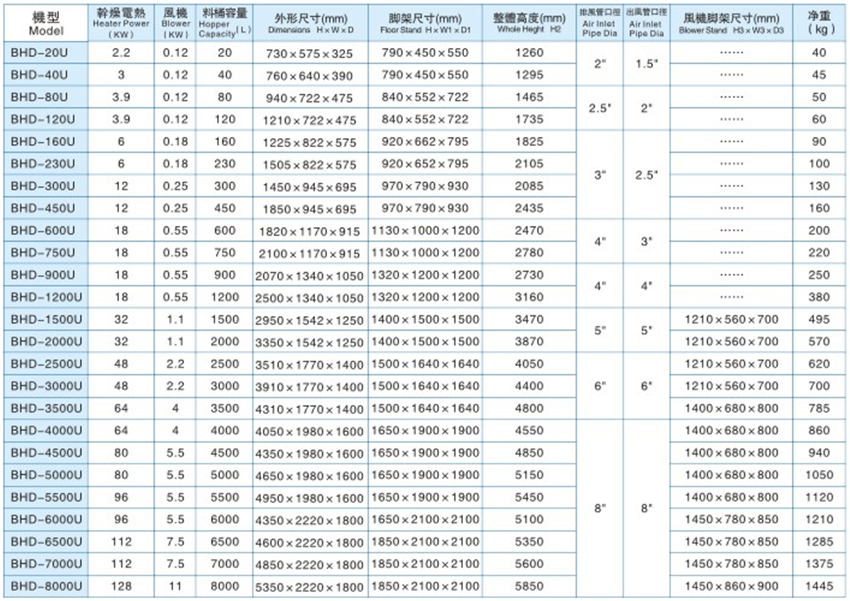

Specifications

We reserve the right to change specifications without prior notice.

Note:

1) For polished hopper inside, plus “P” at model behind.

2) Mark “HT” at the back of models when 180℃high-temp is requested.

3) Blower is included in machine net weight, but floor stand is not included.

4) Power supply:3φ, 230/400/460/575V,50/60Hz.

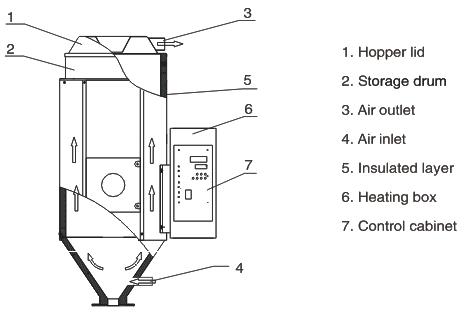

Outline Drawing

BHD-20U~750U(With Optional Floor Stand) BHD-20U~750U(With Optional Floor Stand)

BHD-1500U~8000U(With Optional Floor Stand)

Working Principle

In the drying process, hot air with contstant temperature is blowed by a blower into a two-layer insulated hopper to dry the materials. Moisture will be separated out and taken away by hot air, thus to gain a satisfied drying effect.

The air, generated by blower, will become high-temperature dry hot air after heating by electric heater, and passes a particular down-blowing pipe, so that the hot air can disperse into the storage drum of the hopper evenly to dry the materials into this drum (shown in the above picture). A hot air recycling device can be chosen. The blowing-out hot air will enter the dry blower after being filtered by the recycling device, and this process will form a closed recyclable loop to save electricity power.

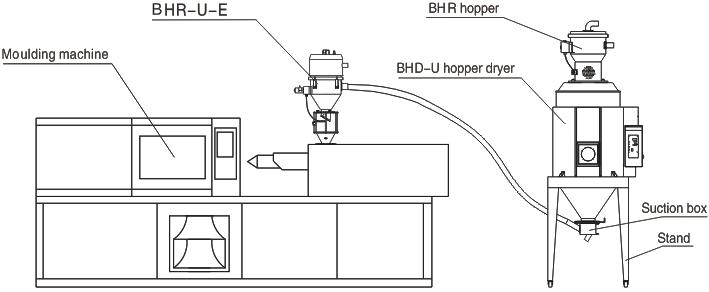

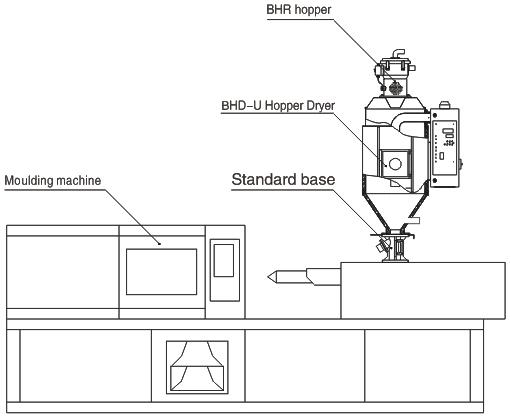

Installation Reference

1. Install directly on a moulding machine

2. To be used with hopper loaders