| QTY: | Price |

Quantity:

-

+

Total Cost :

Packing Information

Pcs/Carton: N/A

Packing Size/Carton:N/A

Packing Vol/Carton: N/A

N.W./Carton: N/A

G.W./Carton: N/A

QTY in 40HQ: N/A

QTY in 40GP: N/A

QTY in 20GP: N/A

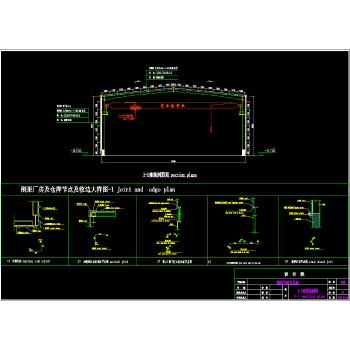

Angola prefabricated steel structure warehouse building built in 2009,a steel warehouse total area is 4000 square meter. Main steel structure used galvanized Hot-rolled H steel. Single steel sheet as roof and wall,no heat insulation.There were two sets 5 Tons 6m lift height overhead crane.The whole structure was connection with bolts,no welded.

Length= 150 meters

Width= 23 meters

Height= 11 meters

Primary Framing Elements-columns, beams and all primary members are made by H section steels- hot rolled section steel/ welded section steel, which will be bolted together at site. A factory primer and facing paintings are applied to get better anti-rusting effect of primary framing elements.

Secondary Framing-Purlin, Tie Bar, Roof and Wall Support are formed as secondary framing

Bracing

Round steel is supplied with knee bracing and other supporting parts that need portal framing, which will improve the stability and durability of the whole structural building.

Cladding

Roof and wall are covering of color-coated corrugated steel sheet or steel sandwich panel, hot dipped with zinc and aluminum compound, that is fixed to the outside of structural building to protect it against bad weather or to make it look more attractive and last for generations.

Windows and Doors

Windows: Plastic Steel Window/Aluminum-alloy Window

Door: Sliding Door/Rolling Door

Other Options

Gutter, Downpipe, Transparent sheet, Ventilator and Bridge Crane will be fitted according to client’s requirements

|

1.Opinions

|

1)We can supply steel structures building for workshop,warehouse,hangar,hotel,apartment,shopping mall,container house, poultry house, modular house, garage, bridge crane, various steel structure materials etc.

|

|

2)We can also make and develop new parts according to customers’ drawings and detailed dimensions.

|

|

|

2.Specifications |

1) Size:

MOQ is 500m2;

Width * Length * Eave Height;

Roof slope;

|

|

2)Type:

Single slope, double slope, Multi-slope;

Single span, double-span, Multi-span;

Single floor, double floors,Multi-floors;

|

|

|

3) Base: steel foundation bolts

|

|

|

4) Steel fream:

Material Q345(S355JR)(Gr50)or Q235(S235JR) steel;

All bolts connection;

Straight cross-section or Variable cross-section;

|

|

|

5) Bracing: X-type or V-type or other type bracing made from angle, round bar, etc ;

|

|

|

6) Wall & Roof C/Z Purlin: Size from C80~C300; Z100~Z300;

|

|

|

7) Roof and wall panel:

Single color corrugated steel sheet 0.326~0.7mm thick;

Sandwich panel with EPS, ROCK WOOL, PU etc insulation, thickness around 50mm~200mm;

|

|

|

8)Window:UPVC or Aluminum Alloy.

|

|

|

9)Door:Sliding or Roller shutter door.

|

|

|

10) Gutter material:Color steel sheet or galvanized steel or stainless steel;

|

|

|

11)Rainspout: PVC pipe

|

|

|

12)Accessories: Skylight panel, Ventilation, Fasteners etc

|

|

|

13)Surface process: Shot blasting Sa2.5;Two lays of Anti-rust Painting!

|

|

|

14) Packing: Main steel frame without packing load in 40’ OT, roof and wall panel load in 40’ HQ!

|