| QTY: | Price |

Supply Ability : 5000SET/ Month

Quantity:

-

+

Total Cost :

Packing Information

Pcs/Carton: N/A

Packing Size/Carton:N/A

Packing Vol/Carton: N/A

N.W./Carton: N/A

G.W./Carton: N/A

QTY in 40HQ: N/A

QTY in 40GP: N/A

QTY in 20GP: N/A

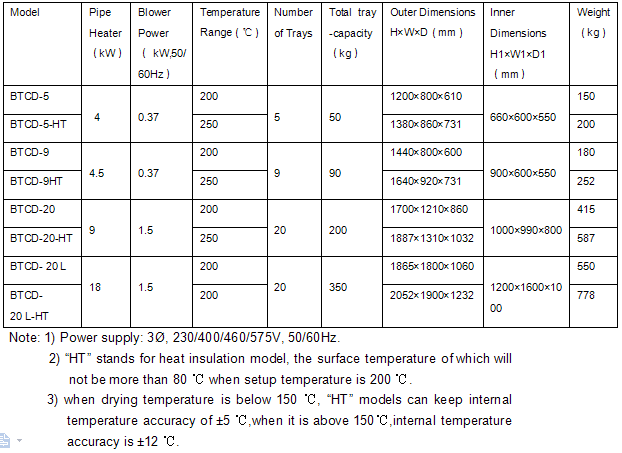

BTCD series of cabinet dryer are mostly used for simultaneous drying of different kinds of polymers in small quantities or for drying materials for trial moulding. They can also be applied in electronic engineering electroplating, pharmacy, paint baking, printing industries, etc. for preheating or drying related products.

BTCD-9

BTCD-9  BTCD-20

BTCD-20

1) Accurate P.I.D. temperature control to achieve an even drying effect.

2) Air-proofed insulative door can maintain temperature constantly inside to reduce energy consumption.

3) Stainless steel tray and liner bring no contamination to materials.

4) Optimal design for ease of maintenance and service.

5) Unique design of adjustable air inlet and exhaust.

6) 24 hours timer, easy to operate.

7) Overheat protector can prevent excessively drying.

8) Motor overload relay.

9) Visible alarm to indicate troubles immediately.

10) Tray size and inner dimensions of the dryer can be specified according to requirements.

11) Upon request, it can be built to comply with worldwide electrical safety standard (For example : CE, UL CSA,JIS etc.).

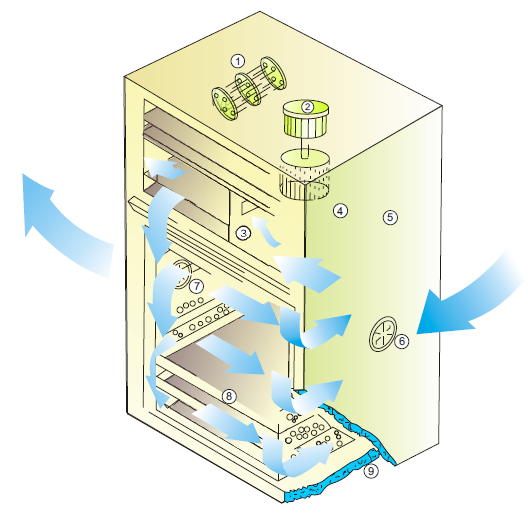

For cabinet dryers, materials to be dried are place on the stainless steel moveable material trays. During operation, process air will flow to heating coil and be heated up to required temperature, then flow through a manifold with evenly scattered holes. Moisture air is set out through air exhaust port. Designed to achieve a uniform drying effect.

1. Heating Coil 2. Air Inlet Blower 3. Air Chamber

4. Multi-vane Impeller 5. Paint-baked Cover 6. Air Inlet

7. Air Exhaust 8. Stainless Steel Tray 9. Heat-resistant Layer