| QTY: | Price |

Supply Ability : 200PCS/ Month

Quantity:

-

+

Total Cost :

Packing Information

Pcs/Carton: 1

Packing Size/Carton:570*370*370mm

Packing Vol/Carton: 0.08 m³

N.W./Carton: 34.0 kg

G.W./Carton: 38.0 kg

QTY in 40HQ: N/A

QTY in 40GP: N/A

QTY in 20GP: N/A

Applications

Planetary ball mill is the requisite equipment for mixing, fine grinding, small sample preparing, new product development and small volume high-tech material production. The instrument has small volume, complete function, high efficiency and low noise. It is the ideal facility to acquire research samples for research institutes, universities as well as enterprise laboratories (can acquire four samples in one experiment). If mated with vacuum ball milling tanks, it can grind samples in vacuum status. The products is extensively applied to in the fields of Geology, Mining, Metallurgy, Electronics, Construction Material, Ceramics, Chemical Engineering, Light Industry Medicine, Environmental Protection etc.

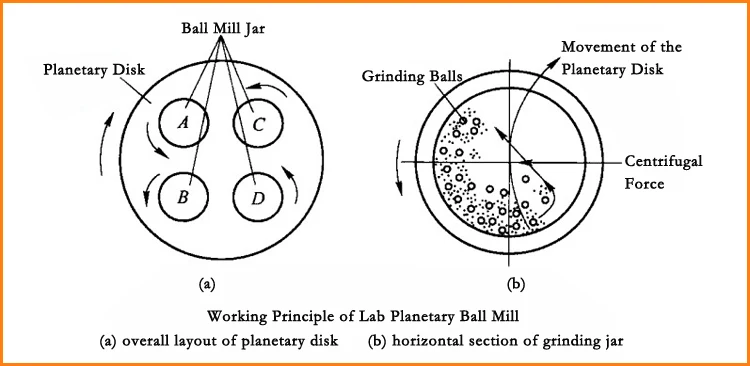

Working Principle

Planetary ball mill has four ball grinding jar holders installed on one planetary disk. When the planetary disk rotates, the jar axis makes planetary movements and the balls in the jars grinds and mixes samples in high speed movement. The instrument can smash and blend various products of different materials and granularity with dry or wet methods. Minimum granularity of grinded products can be as small as 0.1 micron.

Features

Elegant design, easy to operate

Ideal for wet or dry grinding application

Automatic and programmable control with LED display

multiple grinding modes to choose

High Uniformity and excellent repeatability

Fast rotational speed, high efficiency and fine granularity

Four samples with different sizes and materials in one experiment

Programmable interval and pause times

Stepless speed regulation, reversing function

Large range of materials available for grinding tools

Gear-drive offers an effective solution to problems caused by belt driving

Cooling of the grinding chamber with a built-in fan for long grinding times

Technical Data:

2.1 Small Lab Planetary Ball Mill line

|

|

DECO-PBM-V-1L-B |

DECO-PBM-V-2L-B |

DECO-PBM-V-4L-B |

DECO-PBM-V-6L-B |

|

Working Principle |

impact and friction force |

|||

|

Compatible Grinding jar |

(100ml~250ml) *4 |

(250ml~500ml) *4 |

(500ml~1000ml) *4 |

(1000ml~1500ml) *4 |

|

Max Feeding Capacity |

2/3 capacity of the grinding jar |

|||

|

Operation Mode |

2 or 4 grinding jars working simultaneously |

|||

|

Max Feeding Granularity* |

soil materials <= 10mm, other materials <= 3mm |

|||

|

Discharging Granularity |

down to 0.1 micron |

|||

|

Sample Type |

hard, medium-hard, soft, fibrous, brittle, moist – dry/wet |

|||

|

Jar Rotational Speed |

800rpm |

|||

|

Rotational Speed Ratio |

1 : 2 |

|||

|

Dia. of Planetary Disk |

340mm |

340mm |

340mm |

340mm |

|

Drive Mode |

gear drive and belt drive |

|||

|

Speed Control |

stepless speed regulation |

|||

|

Electrical Details |

100-120/220-240 V/1~, 50/60 Hz, 750 Watt |

|||

|

Continuous Grind Time |

Max 72hours (full-load) |

|||

|

Net Weight |

75kg |

75kg |

85kg |

95kg |

|

Gross Weight |

95kg |

100kg |

105kg |

115kg |

|

Dimension |

L720mm*W468mm*H535mm |

|||

|

Package Details |

L800mm*W500mm*H800mm |

|||

* If the sample feed is larger than these then it must first undergo preliminary size reduction.

Structure Details

Photo Show

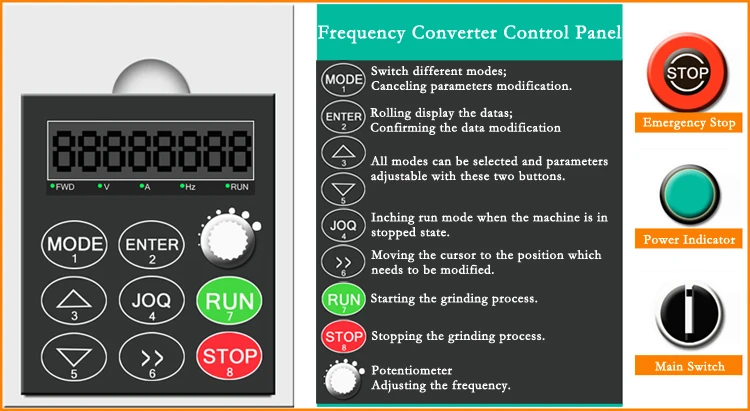

Frequency Conversion Control System

1 Control Panel

2 Main Programs

2.1 Single direction without timing

Samples need long or non-stop milling

2.2 Single direction with timing

Samples need to be milled in one direction for a designated amount of time before automatic shutdown

2.3 Bi-direction with timing

Samples need to run clockwise for 1.5 hours for example, then counter-clockwise for another 1.5 hours and so on, for 15 total hours, before the machine shuts down itself

2.4 Single direction with paused interval and timing

Samples need to run for 0.5 hour for example, then pause for 1 hour, then run for another 0.5 hour in the same direction and pause for another 1 hour, for 20 cycles before auto shutdown

2.5 Bi-direction with paused interval and timing

Samples need to run clockwise for 0.8 hour for example, pause for 0.5 hour, then run counter-clockwise for 0.8 hour, for 20 cycles, before auto shutdown

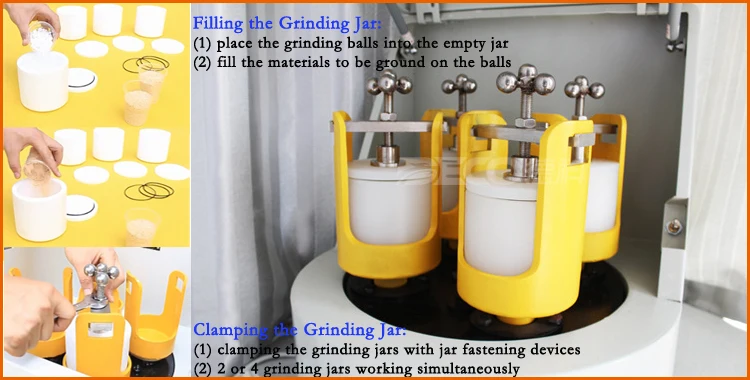

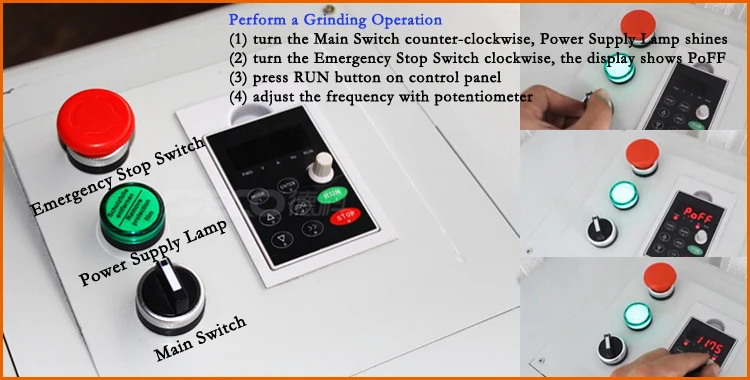

Performing a Grinding Operation

Accessories

Remarks

Please note: for this DECO mill, you require two or four grinding jars of your choice and the corresponding number of grinding balls. The grinding jar material must also be harder than the material to be ground. In normal cases, grinding jars and balls of the same material are used. To shorten the grinding time, larger or heavier grinding jars and grinding balls with a higher density can be used. However, the standard package of the mill doesn't include the grinding jars or balls. They must be ordered as accessories.

Examples of Comminution Tasks

|

Material |

Glass |

Wood |

Ceramic/Sand |

|

Quantity |

500g |

300g |

400g |

|

Material of Ball Mill Jar |

PP |

Nylon /PA6 |

304 Stainless Steel |

|

Jar Volume |

0.5L |

0.5L |

0.5L |

|

Material of Grinding Balls |

Zirconium Oxide |

Zirconium Oxide |

304 Stainless Steel |

|

Ball Diameters |

5/10/20mm |

5/10/20mm |

5/10/20mm |

|

Ball Quantity |

0.8kg |

0.8kg |

0.8kg |

|

Feeding Granularity |

15mm |

10mm |

5mm |

|

Grinding Time |

10min |

10min |

10min |

|

Grinding Mode |

dry grinding |

dry grinding |

dry grinding |

|

Jar Rotational Speed |

500rpm |

500rpm |

500rpm |

|

Discharging Granularity |

~900mesh |

~600mesh |

~800mesh |

Before - After

Related Grinding Tools

Packages

Plastic Wrapping + Styrofoam + Plywood Case

Warranty of Planetary Ball Mill

One year manufactured limited warranty

Free replacement for defective parts due to manufacturing

Any defective must be reported within 7 days after receiving the shipment

DECO reserves right to inspect all defective claims